A supply chain consists of suppliers and customers, or sites acting as suppliers or customers. All such trading partners within a supply chain have the same goal: to satisfy the end customer. One node in a supply chain can sometimes act as a customer and sometimes as a supplier. Some nodes might specialize in manufacturing or stock keeping, while others are experts in order taking.

In order to provide for a supply chain to work efficient from start to end, the different trading partners need information - not only information about the own node, but also information about other nodes in the chain. In order to make a correct decision, a lot of information is needed. However, the following chapters will deal with information that can answer the question: which supplier is most suited to fulfill the customer's request? When a user works with this question, it is called to source. The most important information used in IFS Applications' sourcing functionality is availability, dates, and lead times.

In IFS Applications sourcing can be done:

In both cases, the system calculates availability, dates, and lead times in the same way, and it uses the same data.

When sourcing, the possible supply codes are the following:

When working with sourcing and multiple sites, it is important to know that if two sites do business with each other, these sites must have the same parts defined, and those parts must have the same part numbers. If the exact part number do not exist at both sites, the system will not be able to find the part at the supply site when analyzing the availability, or when trying to create a matching customer order at the supply site. To be more specific, the purchase part number at the demand site must have the same part number as the sales part at the supply site. If the sales part is an inventory part at the supply site, the purchase part number at the demand site must be the same part number as the inventory part at the supply site. Furthermore, to make the inventory valuation work correctly, it is not recommended that you have parts set up as inventory parts at the demand site and non-inventory parts at the supply site, or vice versa. In other words, the sales part type should be the same when sites act within the same legal unit.

When the sourcing takes place, the system uses the total lead time and the availability check. Note that the availability check is only activated if the inventory part at appropriate site has the availability check box selected. The total lead time is dependent on whether the delivery from the supplier will be a transit delivery or a direct delivery; i.e. it is dependent on the supply code. It is also dependent on the ship via code set for the transportation. The total lead time consists of several different lead time parameters originating from different places in the application. However, the most important lead time data is to be found in the supply chain data. You can read more about different lead time parameters and when they are used in the About Lead Time.

When the total lead time is calculated for a supply code where goods should be delivered from a supply site, it is predicted that the goods should be picked from the supply site's inventory. In other words, the sourcing functionality will not consider possibilities to source the internal customer order further at supply site.

Automatic sourcing is when the system uses a sourcing rule to automatically select the most suitable source to supply the customer's demand. Sourcing rules are defined as basic data in IFS Applications. The sales part must be set up to use a sourcing rule, and a sourcing rule should be connected to the sales part alone (inventory as well as non-inventory), to the sales part and the customer, or to the sales part and customer address. If you have connected a sourcing rule to a sales part, as well as a customer and a customer's address, the automatic sourcing will fetch the correct sourcing rule in the following order:

A sourcing rule consists of a source set and sourcing objectives. The source set is a set of all sourcing alternatives. Sourcing alternatives can be external suppliers, internal suppliers, in-house manufacturing, or company inventory. The automatic sourcing will select the best alternative from this set. The best alternative will determine the supply code and, when appropriate, the supplier on the customer order line. The sourcing objectives consist of a sequence of criteria that the automatic sourcing will use when more than one sourcing alternative is suited to supply the customer order line. The following algorithm is used when the automatic sourcing selects the best sourcing alternative:

Note: If no sourcing objectives are set up to separate the sourcing alternatives the algorithm will instead use the priority when selecting the best sourcing alternative. If more than one sourcing alternatives have the same priority, the first alternative will be picked.

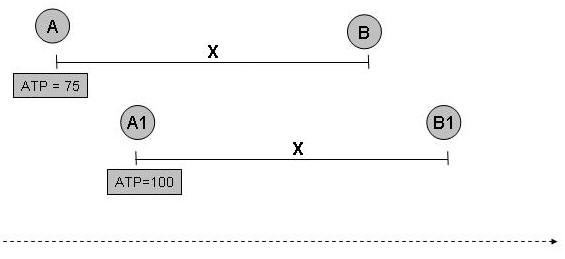

| Example Availability Check: The customer orders 100 and wants to receive the goods on date B. The total lead time is X. The inventory part at the appropriate site (order-taking site or supply site) has the availability checkbox selected. Consequently, the automatic sourcing process checks the availability on date A (B minus X). On A, only 75 are available, thus the calculation checks the availability forwards and finds 100 on date A1. The earliest possible delivery date is B1 (A1 plus X).

|

The sourcing objectives are used when the automatic sourcing have found more than one sourcing alternative. The sourcing objective narrows down the total number of possible alternatives. The different criteria function as follows:

Note that there are no logical restrictions or controls when sourcing rules are defined or when sourcing rules are connected to sales parts, sales part/customers or sales part/customer addresses. Instead these controls take place within the automatic sourcing calculation. For instance, a sourcing rule suggesting shop order as a supply code, will not be activated by the automatic sourcing if the sales part on customer order line is defined as a purchased part in the inventory part record. If the automatic sourcing cannot find an appropriate alternative, you will receive a message that says 'No sourcing alternatives found.' This message will be created by the following controls:

You can run an automatic sourcing only if a connection to a sourcing rule exists. The automatic sourcing is activated in the following ways:

On the customer order line, you can view the result from the automatic sourcing by right-clicking and clicking Sourcing, View Automatic Sourcing Candidates. The candidates shown in the dialog box are the sourcing alternatives that were equally good; they were separated through the sourcing objectives, i.e., the criteria. The Selected check box is selected on the chosen alternatives. For instance: five sourcing alternatives out of seven can deliver the whole sales quantity in time. All five will be shown in the dialog. However, two of the alternatives have the same total shipping time (we assume that only shipping time is used as a criterion). These two will have the Selected check box selected. The automatic sourcing process will pick the first alternative of the two to supply the customer.

When sourcing automatically the system will never suggest a DOP Order or Production Schedule supply code.

Note that it is always possible to change the supply code and the supplier suggested by the automatic sourcing.

In Source Order Lines Manually, you can see the different sourcing alternatives and manually choose the most appropriate alternative. You can choose several alternatives to supply one single order line, i.e., the sales quantity can be split to several sourcing alternatives. Note, when the customer order line originates from an internal purchase order, it is only possible to choose one sourcing alternative. The customer order line must have a Not Decided supply code to be shown in the manual sourcing client. In this window you cannot create sourced lines with a DOP Order or Production Schedule supply code. Neither can you source CTO-parts.

In the tab header in this client, the data in order to source from the site's inventory is shown. For this alternative, you can choose supply code Inventory Order or Shop Order. In the first child table, all suppliers are shown that are connected to the purchase part on the customer order line. All alternatives are shown with Transit as the default delivery mode. If an external supplier is chosen, the supply code will be Purchase Order Transit or Purchase Order Direct on the customer order line depending on whether the delivery mode is transit or direct. If an internal supplier is chosen, the supply code will be Internal Purchase Transit or Internal Purchase Direct on the customer order line depending on whether the delivery mode is transit or direct. In the second child table, the sourced lines are shown. You can delete these records and re-source. To ensure that the available quantity also will be available at a later stage, you can make supply chain reservations from the second child table.

You work mainly in the tab header and in the first child table. The following fields can be updated to find a better sourcing possibility: Wanted Delivery Date, Delivery Mode (only in first child table), and Supplier Ship Via (called Ship Via in tab header). When these fields are updated, the information is re-fetched and recalculated. Supplier Ship Via and Delivery Mode will have an effect on the total shipping time displayed as X in the example below. If you want to change data on the customer order line (for example, change sales quantity), this can be done in the window header or on the customer order line in the Customer Order window.

| Example: The customer orders 100 and wants to receive the goods on date B. The total lead

time is X (called total shipping time in the client). The inventory part at the appropriate site (order-taking site or supply site) has the availability checkbox selected. Consequently, the

manual sourcing checks the availability on date A (B minus X). On A only 75 are available, thus the calculation checks the availability forwards and

finds 100 on date A1. The earliest possible delivery date is B1 (A1 plus X). The fields that provide the information described in the example, are the

following:

Supply Site Due Date (A) It is only relevant to show ATP on date A not on date A1. Consequently, note that ATP = 75 is shown in the manual sourcing window; 100 is the customer's ordered quantity. Also note that the sourced quantity and ATP is always calculated and shown in the inventory unit of measure.

|

As long as the customer order line is not yet completely sourced, i.e., sourced quantity differs from revised quantity, you cannot release that customer order line. However, you can release the order as a whole, which means that the order head will receive a Released status and the rest of the customer order lines will be released. The customer order line that is not yet completely sourced, can be released at a later stage by right-clicking, pointing to Sourcing, and then clicking Release Source Line. When a sourced order line is being released, each source line originating from the same customer order line receives a separate customer order line, and, when appropriate, correct orders are created (shop order, purchase order, etc.). Even after a customer order is released (as long as the customer order header status is less than Delivered), you can enter new order lines with a Not Decided supply code and source them manually via Source Order Lines Manually.

Sourced lines that originates from an order line have the originating order line's delivery number defined on its customer order line. This is shown in the field Originating Del No.

For each customer, you can define whether the external printouts sent to the customer should show all order lines originating from one order line or if the documents should summarize these order lines. The default value is defined in a check box in the Customer window, and this value is copied into the customer order and shown on the Document Information tab. You can change the value on the customer order. So far, it is only on order confirmation that will be summarized.

You can reach the manual sourcing client from the following windows:

Note that you can always override suggested supply code and suggested supplier on a customer order line, as long as the customer order header status is Planned. However, some restrictions exist if inventory reservations have been made. Also remember that if the customer order line does not have any sourced lines, you can always choose to source automatically.