IFS/Manufacturing has flexible reservation management which can vary, depending on the requirements for delivery assurance for different parts. When a shop order is entered, material that should be used in the shop order is identified. This is only a general reservation; it does not indicate exactly from which locations the material that is used is located on. To reserve material, the shop order should be in the Released status or higher.

You can reserve material for a shop order automatically for the entire order. When you do that, you can specify a date up to which the reservations should be made. This means that you do not have to reserve all the materials at once, you only need to reserve material needed up to that particular date. You can also order an on-hand analysis and automatically print the pick list when you reserve the shop order.

Material can also be reserved automatically for one material line at a time as well as for one or several operations at a time. By linking material to the operation in which it will be used, you do not have to reserve material too far ahead in time. This is a way of making sure that material is not reserved for an unnecessarily long period of time. When material is connected to a operation, they will be issued when the operation is reported.

Alternatively, you can reserve material for a shop order manually. This option allows you to select the inventory location and quantity to be reserved.

If you park a shop order that has reserved material, the park reason you select decides whether the reservations will be removed or kept.

Availability checks are a major part of IFS/Manufacturing. Each time a part is received into or issued from inventory, its quantity on hand changes. In the same way, the availability of the part changes each time you plan an issue or receipt. The availability check monitors the development of the available balance within the product's lead time. This means that each time a change occurs, the system determines whether all shop orders can be delivered on the promised date. The change can be an order entry, an issue, or a reservation. Only changes within the part's lead time are taken into account, since the availability of the part outside the lead time is considered to be under control. It is possible to decide on each component if the availability check should be enabled or not, Inventory Part, Misc Part Info tab, Availability Check.

When you reserve material for a shop order, the material cannot be used for any other shop order and it should be determined that the current shop order will not have a shortage in materials as well. You cannot reserve more material than the demand.

When material is reserved automatically, it is reserved from an inventory location that is selected according to the given reservation hierarchy. Reservation logic will be triggered for all the material lines with Reserve/Issue Method on the shop order material line set to Reserve or Reserve and Backflush. Material lines set to Backflush will not be included in the automatic reservation.

When reservation is done manually the reservation hierarchy will be bypassed and it is possible to reserve material from all the available locations. By manually reserving material, you ensure that you get material from the exact location you want. Also material lines with Reserve/Issue Method on the shop order material line and set to Backflush can be manually reserved.

Use this function to unreserve previously reserved material. Note that the shop order should be in the Reserved status before you can use this function.

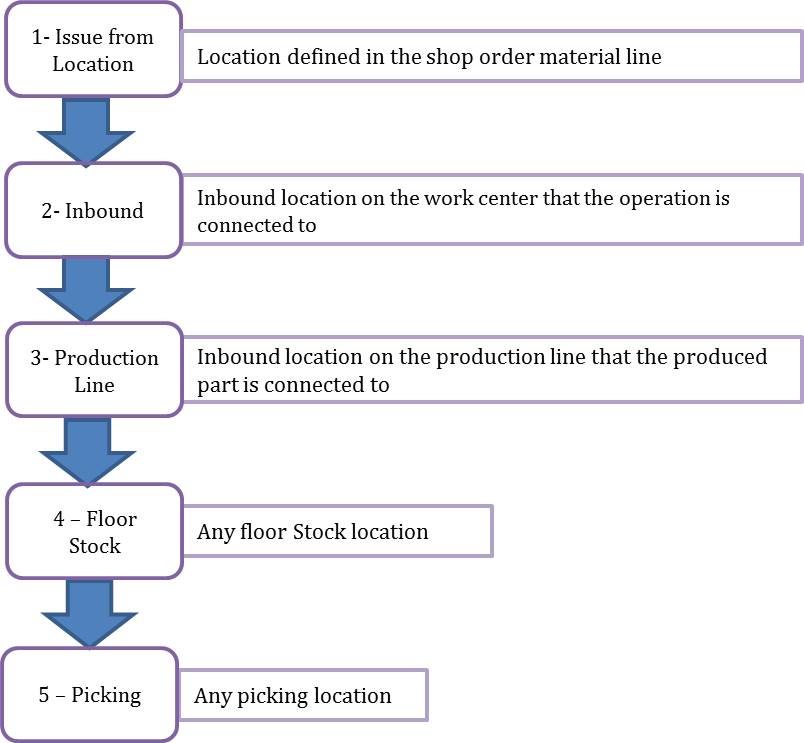

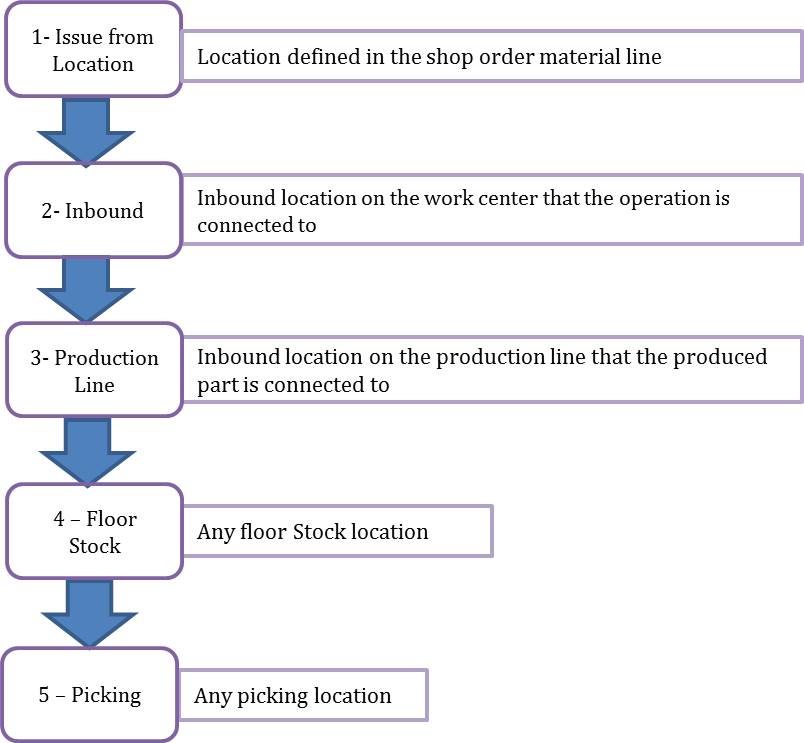

When the shop order material line is evaluated to be reserved automatically, there is a well defined reservation hierarchy that is triggered. There are 5 levels in this hierarchy and depending on the parameter setup, it is possible to decide how depth the logic should continue as well as what locations that should be evaluated in each level. On the shop order material line, there is a right-click option to navigate to Reserve and Backflush Visualization. That will open up a dialog box that shows the reservation hierarchy and the relevant parameters for the logic.

If there is a location given in Issue From Loc field on shop order material line, material will be reserved from that location, if material is available there. If material is not enough, and the component has the Inventory Part setting for Backflush Part set to All Locations or Only Floor Stock, the logic will continue. If all is reserved or if Backflush Part is set to Only Specified Location, the logic will stop at level 1.

If the material line is connected to an operation, the next level for evaluating is work center inbound locations. If the work center on the connected operation has inbound locations defined, they will be evaluated first. It will be done by starting on the floor stock locations and then picking locations defined on the work center as inbound locations. On work center inbound locations, there is also an option to decide if the location should be shared or not. If not shared, the inbound location will not be available for reserving and backflush on level 4 and 5 in the hierarchy. This only affect material lines that is not connected to operations which are connected to the work center on level 2. If material is not enough, and the work center has the setting for Outside Reserve/Backflush set to Reserve Allowed or Reserve and Backflush Allowed the logic will continue. If all is reserved or if Outside Reserve/Backflush on the work center is set to either Backflush Allowed or Not Allowed, the logic will stop at level 2. This level will not be evaluated if the material line is not connected to an operation.

If the part produced on the shop order is connected to a production line the next level for evaluating is production line inbound locations. If the connected production line has inbound locations defined, they will be evaluated. It is only possible to set up inbound locations of type production line, this is the only time in the hierarchy where production line locations are evaluated. If material is not enough on the inbound locations, and the production line has the setting for Outside Reserve/Backflush set to Reserve Allowed or Reserve and Backflush Allowed the logic will continue. If all is reserved or if Outside Reserve/Backflush on the production line is set to either Backflush Allowed or Not Allowed, the logic will stop at level 3. This level will not be evaluated if the produced part is not connected to a production line.

If there are any floor stock locations that has not yet been evaluated, they will be evaluated at this step. If a floor stock location has the flag for Shared location unchecked, the automatic reservation will not be able to reserve from such location on hierarchy level 4. If not enough material is available, and Backflush Loc on Inventory part for the component is set to All Locations, the logic will continue. If all is reserved or if Backflush Loc on Inventory part for the component is set to Only Specified Location or Only Floor Stock, the logic will stop at this level.

If there are any picking locations that has not yet been evaluated, they will be evaluated at this step. If a picking location has the flag for Shared location unchecked, the automatic reservation will not be able to reserve from such location on hierarchy level 5. The logic will stop at this level.